TAM-6-165

Mechanical Diaphragm Dosing Pump 460 L / Hour at 5.0 Bar

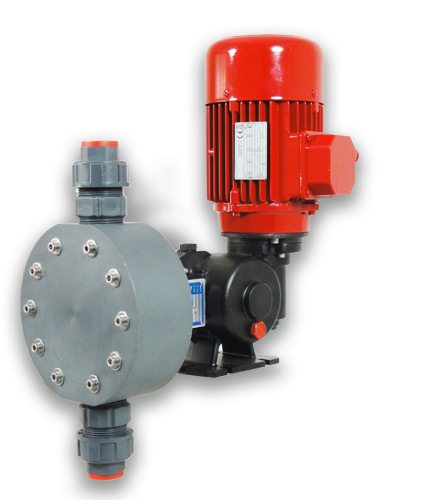

TAM-6-165 Mechanical Diaphragm Dosing Pump, here pictured with a PVC head, available with a choice of 3 gearbox sizes.

TAM-6-165 Mechanical Diaphragm Dosing Pump Introduction

The TAM-6-165 Mechanical Diaphragm Dosing Pump works on a cavity displacement principle with a reciprocating PTFE diaphragm. The linear volumetric displacement enables steady, even and continuous chemical metering.

As a process device, the TAM-6-165 is designed to deliver defined amounts of chemical reagent with high precision. Manufactured with an aluminium body and foot mounting stand, the TAM-6-165 is designed to be horizontally mounted and connected to a process using the 1" BSP connections.

The TAM-6-165 is driven from a 3 phase 0.37kW 400VAC motor and is also available with a single phase 0.55kW 230VAC motor.

TAM-6-165 Mechanical Diaphragm Dosing Pump Head Options

The TAM-6-165 Dosing Pumps is available with a choice of four head material types inlcluding PolyPropylene, PVC, PVDF or 316 Stainless Steel. All the head options on the TAM-6-165 are paired with a PTFE diaphragm measuring 165mm Ø. The stroke length of the TAM-6 series is 6mm.

As well as the options for head material, the other liquid end components (otherwise known as wetted parts) which constitutes the materials in contact with the solution to be dosed, are available in a sellection of materials to provide greater compatibility with a range of chemicals.

| Head Material | Diaphragm Material | Seal Material | Ball Valve Material | Valve Seat Material | Connections |

|---|---|---|---|---|---|

| Polypropylene | PTFE | N/A | Ceramic / PTFE | N/A | 1" BSP |

| PVC | PTFE | N/A | Ceramic / PTFE | N/A | 1" BSP |

| PVDF | PTFE | N/A | Ceramic / PTFE | N/A | 1" BSP |

| Stainless Steel | PTFE | 316 Stainless Steel | 316 Stainless Steel | 316 Stainless Steel | 1" BSP |

The TAM-6-165 has 1" BSP connections on all head materials and gearbox sizes. Unlike the smaller TAM-2 and TAM-4 series of mechanical diaphragm dosing pumps, the TAM-6-165 doesn't have any seals or O-rings in contact with the chemical to be dosed.

The TAM-6-165 uses a double ball valve for both the suction side and discharge side of the pump, to aid both priming of the pump and to ensure precision chemical delivery during operation.

You can check the material compatibility using our material compatibility database and we also recommend that you check with your chemical supplier, to ensure that all the parts of the liquid end are compatible with the chemical to be dosed.

TAM-6-165 Gear Box Options

As with all the pumps in our TAP range, the TAM-6-165 is available with a fixed speed gear box to give either 58 strokes per minute, 78 strokes per minute or 116 strokes per minute.

By increasing the number of strokes per minute, the output flow rate of the pump changes as per the following table:-

| Model Number | Strokes / Minute | Flow (L/Hr) | Pressure (Bar)* | Connections |

|---|---|---|---|---|

| TAM-6-165-58 | 58 | 0 - 230.0 | 5.0 | 1" BSP |

| TAM-6-165-78 | 78 | 0 - 330.0 | 5.0 | 1" BSP |

| TAM-6-165-116 | 116 | 0 - 460.0 | 5.0 | 1" BSP |

Mechanical Diaphragm Dosing Pump Adjustable Flow Rate

The TAM-6-165 has a micrometer stroke length adjustment dial, mounted at the side of the pump. This allows the stroke length to be reduced from the maximum length of 6mm so that the flow rate can be set to anywhere between 0 - 100% of the strokes maximum output. (To maintain accuracy we don't advocate running the pump below 20% of the rated output).

TAM-6-165 Features & Benefits

The TAM-6-165 Mechanical Diaphragm dosing pump is a foot mounting mechanical diaphragm dosing pump, designed to be secured on a horizontal surface to deliver a chemical reagent to a process.

With a choice of 316 Stainless Steel, PolyPropylene, PVC, or PVDF head materials, all combined with a PTFE diaphragm and no valve seals or O-rings, the TAM-6-165 is compatible with a wide range of chemical reagents, including concentrated chemicals. Please don't hesitate to contact us for advice or check with your chemical supplier to ensure compatibility with your process.

With a PTFE diaphragm and accurately machined and assembled components, the TAM-6-165 is designed to meter a defined volume of chemical, steadily and evenly into a process with high precision.

The TAM-6-165 can be fitted with either a 0.37kW 3 phase 415 VAC motor or a 0.55kW 3 phase 230 VAC motor.

Each motor drives a gearbox which either outputs 58, 78, or 116 strokes per minute with an output of 230.0 Litres / Hour, 330.0 Litres / Hour, or 460.0 Litres / Hour respectively. Each option has a maximum pressure output of 5.0 Bar when using with any combination of head materials. All the head options use 1" BSP connections for easily connecting directly into a process.

With a micrometer adjustment, the output rate of the pump can be user adjusted between 0 - 100% of the flow rate, to give greater control over your chemical dosing.

The TAM-6-165 is a fully compatible with a range of dosing accessories, including: pulsation dampeners, anti-syphon, back pressure and safety valves.

TAM-6-165 Specifications

-

Specifications

Piston Dosing Pump

Model Number:- TAM-6-165

Pressure:- 5.0 Bar

Max Flow Rate 58 Strokes / Min:- 230.0 Litres / Hour

Max Flow Rate 78 Strokes / Min:- 230.0 Litres / Hour

Max Flow Rate 116 Strokes / Min:- 460.0 Litres / Hour

3 Phase Motor:- 0.37kW 400V AC

Single Phase Motor Option:- 0.55kW 230V AC

PTFE Diaphragm Diameter:- 165mm

Stroke Length:- 6mm

TAM-6-165 Connections:- 1" BSP

Head Material Options:- Polypropylene, 316 Stainless Steel, PVC, or PVDF

Dimensions PP, PVC, PVDF:-

- X:- 377 mm

- Y:- 160 mm

- W:- 193 mm

- Weight:- 13.3 Kg

Dimensions Stainless Steel:-

- X:- 269 mm

- Y:- 157 mm

- W:- 190 mm

- Weight:- 22.0 Kg

-

Data Sheets

-

Ordering Information

Model Number Strokes / Min Head Material Balls Seals Flow (L/Hr) Pressure (Bar) Connection Size TAM6-165-58-PP-C-D 58 Polypropylene Ceramic EPDM 0 - 230 5.0 1" BSP Male TAM6-165-58-PP-C-V 58 Polypropylene Ceramic Viton 0 - 230 5.0 1" BSP Male TAM6-165-58-PP-P-D 58 Polypropylene PTFE EPDM 0 - 230 5.0 1" BSP Male TAM6-165-58-PP-P-V 58 Polypropylene PTFE Viton 0 - 230 5.0 1" BSP Male TAM6-165-58-PVC-C-D 58 PVC Ceramic EPDM 0 - 230 5.0 1" BSP Male TAM6-165-58-PVC-C-V 58 PVC Ceramic Viton 0 - 230 5.0 1" BSP Male TAM6-165-58-PVC-P-D 58 PVC PTFE EPDM 0 - 230 5.0 1" BSP Male TAM6-165-58-PVC-P-V 58 PVC PTFE Viton 0 - 230 5.0 1" BSP Male TAM6-165-58-PVD-C-D 58 PVDF Ceramic EPDM 0 - 230 5.0 1" BSP Male TAM6-165-58-PVD-C-V 58 PVDF Ceramic Viton 0 - 230 5.0 1" BSP Male TAM6-165-58-PVD-P-D 58 PVDF PTFE EPDM 0 - 230 5.0 1" BSP Male TAM6-165-58-PVD-P-V 58 PVDF PTFE Viton 0 - 230 5.0 1" BSP Male TAM6-165-58-SS 58 316 SS 316 SS N/A 0 - 230 5.0 1" BSP Male TAM6-165-78-PP-C-D 78 Polypropylene Ceramic EPDM 0 - 330 5.0 1" BSP Male TAM6-165-78-PP-C-V 78 Polypropylene Ceramic Viton 0 - 330 5.0 1" BSP Male TAM6-165-78-PP-P-D 78 Polypropylene PTFE EPDM 0 - 330 5.0 1" BSP Male TAM6-165-78-PP-P-V 78 Polypropylene PTFE Viton 0 - 330 5.0 1" BSP Male TAM6-165-78-PVC-C-D 78 PVC Ceramic EPDM 0 - 330 5.0 1" BSP Male TAM6-165-78-PVC-C-V 78 PVC Ceramic Viton 0 - 330 5.0 1" BSP Male TAM6-165-78-PVC-P-D 78 PVC PTFE EPDM 0 - 330 5.0 1" BSP Male TAM6-165-78-PVC-P-V 78 PVC PTFE Viton 0 - 330 5.0 1" BSP Male TAM6-165-78-PVD-C-D 78 PVDF Ceramic EPDM 0 - 330 5.0 1" BSP Male TAM6-165-78-PVD-C-V 78 PVDF Ceramic Viton 0 - 330 5.0 1" BSP Male TAM6-165-78-PVD-P-D 78 PVDF PTFE EPDM 0 - 330 5.0 1" BSP Male TAM6-165-78-PVD-P-V 78 PVDF PTFE Viton 0 - 330 5.0 1" BSP Male TAM6-165-78-SS 78 316 SS 316 SS N/A 0 - 330 5.0 1" BSP Male TAM6-165-116-PP-C-D 116 Polypropylene Ceramic EPDM 0 - 460 5.0 1" BSP Male TAM6-165-116-PP-C-V 116 Polypropylene Ceramic Viton 0 - 460 5.0 1" BSP Male TAM6-165-116-PP-P-D 116 Polypropylene PTFE EPDM 0 - 460 5.0 1" BSP Male TAM6-165-116-PP-P-V 116 Polypropylene PTFE Viton 0 - 460 5.0 1" BSP Male TAM6-165-116-PVC-C-D 116 PVC Ceramic EPDM 0 - 460 5.0 1" BSP Male TAM6-165-116-PVC-C-V 116 PVC Ceramic Viton 0 - 460 5.0 1" BSP Male TAM6-165-116-PVC-P-D 116 PVC PTFE EPDM 0 - 460 5.0 1" BSP Male TAM6-165-116-PVC-P-V 116 PVC PTFE Viton 0 - 460 5.0 1" BSP Male TAM6-165-116-PVD-C-D 116 PVDF Ceramic EPDM 0 - 460 5.0 1" BSP Male TAM6-165-116-PVD-C-V 116 PVDF Ceramic Viton 0 - 460 5.0 1" BSP Male TAM6-165-116-PVD-P-D 116 PVDF PTFE EPDM 0 - 460 5.0 1" BSP Male TAM6-165-116-PVD-P-V 116 PVDF PTFE Viton 0 - 460 5.0 1" BSP Male TAM6-165-116-SS 116 316 SS 316 SS N/A 0 - 460 5.0 1" BSP Male All diaphragms are manufactured in PTFE.

Pump heads in 316 Stainless Steel are metal seated with Stainless Steel ball valves.

Please use our chemical compatibility checker to ensure that the wetted parts are compatible with your process. If you're unsure please don't hesitate to contact our friendly sales team.