All About Chemical Dosing Pumps.

What Are Dosing Pumps?

A Chemical Dosing Pump or "metering pump" is designed to dose a precise volume of chemical reagent into a process. They are often used to pump chemicals or solutions, to a process vessel or pipework, usually pumping from a chemical drum that's either 25L, 205L or an IBC. We also offer a range of chemical dosing tanks from 50 to 1000 litre capacity.

Usage of a Dosing Pump

A dosing pump can have a wide variety of uses. They are typically for injecting either a chemical or a solution into a system to start a chemical reaction. From neutralising pH to creating a product, the application of dosing pumps are numerous from simply dosing swimming pool water to complex batch operations of chemical reagents into process vessels.

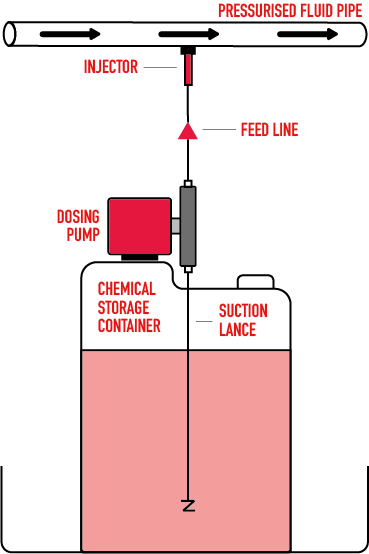

A Typical dosing system consists of:

- A Dosing Tank and Bund Tank consisting of the chemical you wish to input into the system.

- A Suction Lance Assembly in the tank often with low level output and a non return valve.

- A Dosing Pump which may have manual output adjustment or automatic output adjustment.

- Dosing tubing in a material non reactive to the chemical to safely carry the chemical reagent.

- An Injector fitting with suction NRV (non return valve) to prevent bulk feeding of the process' solution.

Foot Mounting, Surface Mounting & Control Functions.

Dosing pumps are availabe for mounting onto flat horizontal surfaces such as tank tops or shelves, known as foot mounting pumps. Or for mounting on flat vertical surfaces such as wall mounting or on back plates for when dosing into manifolds.

Dosing pumps are available with many different control functions. These include: Manual output adjustment via a potentiometer usually 0 -100% of the pumps rated output such as the AT2-BX dosing pump, (the BX signifies its manual output adjustment). Manual Output with low chemical cut-out via a potentiometer usually 0 -100% of the pumps rated output with a low level float switch connection to stop the pump running dry. Manual or automatic output control is selectable. Manual control with a potentiometer, or automatic control via an electrical signal which is selectable for PFM pulse frequency modulation, which are a series of VFC (Volt free contact) closures or pulses usually from a contacting head water meter; an AWE Limited pH Controller; a PLC or a 4-20ma control signal from a Process Controller.

Choosing the right Chemical Dosing Pump for you.

Water Treatment, Effluent Treatment and Process Control applications often include a requirement to add a chemical reagent to a process. This is why choosing the right dosing pump for you is so important. There are significant variables that could impact your decision, including the type of chemical reagent to be added. Also the flow rate, the pressure and the nature of the control process. This is why our online chemical compatibility checker should be used. With this you can check a range of chemicals against the parts of a dosing pump, or check the material of a dosing pump against the chemical so as to ensure that the pump doesn't degrade over time and for the safety of those working with dangerous chemicals.

Depending on the application you might need a specific type of pump for your process; either to allow automation or to integrate some of the process into the pump.

Dosing Up Hill & Down Hill

Learn all about dosing up and down hill and how to resolve any problems you have.

Double Confinement Chemical Dosing

Learn about double confinement dosing and how it can benefit you.