CP721-10

Peek Insertion Conductivity Cell with K=1.0

The CP721-10 Insertion Conductivity Cell with cell constant K=1.0 manufactured in PEEK.

CP721-10 PEEK Insertion Conductivity Cell Introduction

The CP721-10 is an electrolytic conductivity measuring cell designed for the continuous measurement of conductivity directly in tanks, vessels, and large bore pipework.

Manufactured with carbon graphite electrodes, epoxy resin and PEEK (Polyether Ether Ketone), the CP721-10 offers enhanced thermal and chemical resistance. Designed predominantly for use where elevated temperatures and aggressive chemicals may be in use.

The CP721-10 is designed for operation at temperatures up to 120°C and at a pressure of 10 Bar at 20°C.

One key feature of the CP721-10 PEEK Insertion conductivity cell is that the threads and the sensor body are manufactured from the same material. This eliminates premature failure caused by cycling temperatures and differing thermal expansion coefficients.

The CP721-10 uses proven manufacturing techniques enabling us to offer a PEEK conductivity cell with a high linearity. This means that the effective range of the CP721-10 with a cell constant of K=1.0 is up to 50.0mS (50'000µS).

In addition, the CP721-10 can be fitted with an integral temperature measuring device to provide temperature compensation to a compatible conductivity instrument.

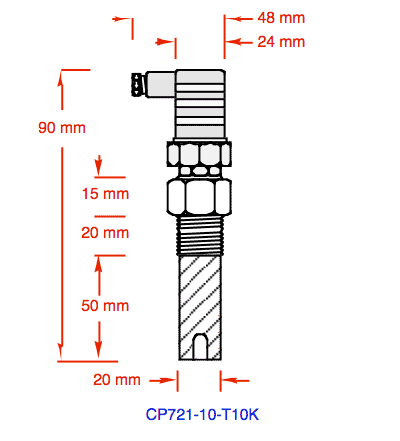

For installation purposes, the CP721-10 uses a 3/4" threaded BSP connection, allowing the PEEK conductivity cell to be screwed directly into process vessels or pipework. In addition, the CP721-10 uses our unmountable head, allowing the head to be completely removed during installation, or for periodic calibration and maintenance.

PEEK Insertion Conductivity Cell CP721-10 Features & Benefits

The materials of construction for the CP721-10 mean that it is well suited to operation in environments with aggressive chemicals or frequent changes in temperature, up to 120°C.

The CP721-10 is ideally used in water purity control; solution strength control applications; CIP detergent strength control in food and dairy industries and steam condensate return measurements.

Offering high linearity and good thermal and chemical resistance, this model offers an upper conductivity measuring range of up to 50.0mS, as well as an integrated temperature sensor for automatic temperature compensation, making the CP721-10 a very versatile sensor.

The CP721-10 is often paired with the C7685 conductivity controller.

CP721-10 PEEK Insertion Conductivity Cell Specifications

-

Specifications

Insertion Conductivity Cell

Model No:- CP721-10

Cell Constant:- K=1.0

Measuring Range:- 0 - 50.00mS

Materials of construction Cell:- PEEK (Polyether ether ketone) Epoxy resin, Carbon Graphite Electrodes

Max temperature:- 0-120°C

Max pressure:- 10 Bar at 20°C

Temperature Compensation:- Available

Connections:- Fixed Connections or de-mountable Connector

-

Features

- Electrolytic conductivity measuring cell with a proven design for accurate and reliable conductivity measurement.

- Manufactured in materials designed to offer greater chemical and thermal resistance for operation where aggressive chemicals are present.

- High linearity cell constant of K=1.0 for measurements of conductivity values below 50.00mS.

- High thermal resistance threshold and as the CP721-10 is an all PEEK bodied conductivity cell with a common thermal expansion coefficient, premature failure due to thermal expansion is eliminated.

- Designed for demanding processs conductivity measurements including water purity, solution strength control, CIP detergent strenght control in food and dairy industries as well as for steam condensate rerun measurement.

- Optional integral temperature measuring device to provide automatic temperature compensation to a compatible instrument.

-

Data Sheets