Old Tricks Solution Strength Control

Many industrial process which use chemical solutions such as sulphuric acid, hydrochloric acid, potassium chloride sodium hydroxide or potassium hydroxide to name a few can often use conductivity to control the solution strength. Many industrial process which use chemical solutions such as sulphuric acid, hydrochloric acid, potassium chloride sodium hydroxide or potassium hydroxide to name a few can often use conductivity to control the solution strength.

Many industrial process which use chemical solutions such as sulphuric acid, hydrochloric acid, potassium chloride sodium hydroxide or potassium hydroxide to name a few can often use conductivity to control the solution strength. Many industrial process which use chemical solutions such as sulphuric acid, hydrochloric acid, potassium chloride sodium hydroxide or potassium hydroxide to name a few can often use conductivity to control the solution strength.

This can be achieved with our low maintenance cost effective conductivity controller model C3655-W which uses an electrodeless cell. Sometime time referred to as inductive due to the principal of operation or torrodial due to the shape the sensor basically they are very similar.

The electrodeless cell works on the principal of a transformer where two coils are placed close together incased in a suitable chemical resistance non conducting material, with a hole between the two isolated coils for the solutions to pass through.

The solution acts as the plates of the transformer, the greater the conductivity the larger the signal induced from one coil to the other which is then amplified in the instrument or transmitter and used to display conductivity.

The advantage is no electrodes become fouled up with dirty solution unless the centre hole in the cell is completely blocked with sludge or solids. The disadvantage is electrodeless cell work best on higher conductivities, so not suitable for denim water or tap water. This is no problem to us as these solutions work just fine with our standard contacting cells.

Our C3655-WK comprises of a wall mounting controller in a corrosion resistant weatherproof housing, available with one of three ranges 0-20.00 mS, 0-200.0 mS or 0-2000 mS with auto temperature compensation to a base of 25oC. Ie all the readings are compensated back to 25oC A single adjustable control relay with a delay timer is fitted to control dosing equipment and an isolated 4-20mA current output for connection to our paperless recorder/data logger, your BMS system or remote indicator.

For use in open tanks we are able to supply the Model DEC1 electrodeless dip cell in PVDF with cPVC riser tube and a mounting flange with an option for polypropylene, PVDF or stainless steel riser tubes for higher temperature sure and greater chemical resistance. We are able to supply inline cells please contact us with your requirements. The cell is designed for mounting close to the Model C3655-W controller for easy calibration.

The Model C3655-W is ideal for controlling a local dosing pump or as a transmitter to provide a 4-20mA signal for remote control.

Mag Flow Meter Installation

We regularly supply inline flow meters usually magnetic for meters which work well when correctly installed.

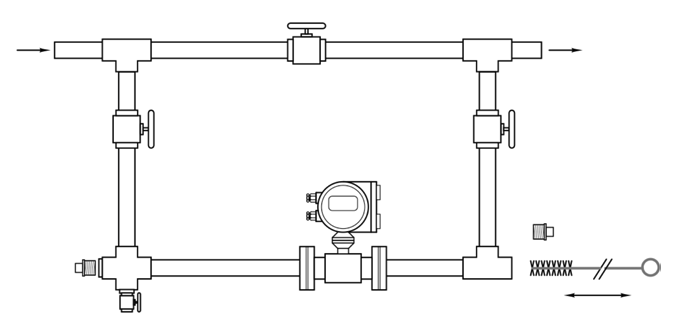

They require a level straight piped inlet with no valves or elbow of five times the pipe diameter before the meter and three times the pipe diameter after the magnetic flow meter.

The pipework must be arranged so the pipe is always full ( the 5 x and 3 x may vary with manufacture). This can make cleaning the inside of the magnetic flow meter difficult when bolted into the pipework.

However if the meter is installed in the bottom of a “u” section of pipework with a “tee” at each end with a threaded blanking plug in the tee at each end of the “u” section which can be easily removed, a large bottle type brush can be used" "to clean the pipework and meter without removing the meter.

Take care to follow all H & S rules regarding isolating the pipe and locking off isolation valves before draining the pipework and isolating any electrical supplies before starting work.

Applications for magnetic flow meters include batching towns" "water into a process vessel. Measuring the flow of chemical reagents into process vessel when connected to our batching control system. Incoming water flow into a production area for production costing and waste water flow to discharge to sewer of water course as part of our waste water" "monitoring system.

Electrodeless Conductivity Transmitter 2 Wire

After our article regrading the Model C3655-W electrodeless conductivity controller we have just supplied some electrodeless conductivity transmitter for measuring seawater pH and conductivity at a Chinese power station the conductivity range was 45 to 55mS. So an ideal range for our BCT100 two wire transmitter which is available with factory calibrated ranges of either 0 - 10 mS, 0 - 100 mS or 0 - 1000 mS corresponding to a 4 - 20 mA industry standard current output. Being a two wire transmitter the same 2 wires which power the transmitter also carry the 4 - 20 mA current output. This makes the installation simple just a two core screened cable type LMK2 to install ache could be several hundred metres with no loss of signal.

Our Model BCT100 two wire conductivity transmitter which will interface to their SCADA system.

As well as fitting into a large diameter pipework 75 mm or larger the Model BCT100 blind conductivity transmitter range 0-100mS are available for dip or submersible use in tanks and pits with solution temperatures up to 50oC.

The Model BC7635 slave controller with built in 24 V power supply is ideal to power the Model BCT100 and provided two control relays an alarm relay and an isolate4d 4 - 20 mA signal for retransmission to a remote indicator, data logger or site SCARDA system, remember you heard it on the AWE Grapevine.