Mechanical Diaphragm Dosing Pump

Our TAM range of mechanical diaphragm pumps are designed for process applications where the precise metering of chemical is required. The TAM pump series all work using volumetric cavity displacement to ensure that the chemical is metered accurately into the process with a linear relationship between the stroke length and the amount of chemical dosed into the process.

The TAM range differs from our piston dosing pump range in the method of delivery. In the piston dosing pump the piston is directly in contact with the liquid, whereas in the TAM pump a diaphragm is attached to the piston. This results in only the PTFE face of the diaphragm and the pump head itself being in contact with the chemical, which is dosed as the reciprocating movement of the diaphragm causes a volumetric displacement inside the head of the pump.

The PTFE diaphragm is very chemically resistant and when paired with the appropriate head material for your application, should ensure compatibility with a wide range of chemical reagents including concentrated chemicals.

Mechanical Diaphragm Pump - Head Sizes

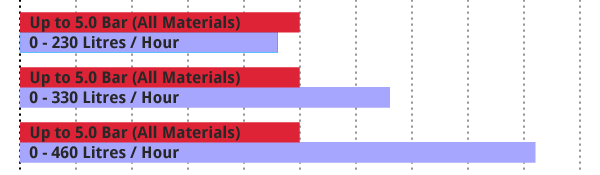

The TAM Series of dosing pumps are available with 4 different head sizes to allow for a wide range of discharge pressure and discharge flow rates. The TAM series can output at a maximum pressure of 10.0 Bar or a flow rate of 460 Litres / Hour.

Each of the different head sizes comprises of a different sized PTFE diaphragm which results in a different output flow rate. The corresponding diaphragm sizes are listed below:-

| Model Number | PTFE Diaphragm Diameter |

|---|---|

| TAM-2-94 | 94 mm |

| TAM-4-108 | 108 mm |

| TAM-6-135 | 135 mm |

| TAM-6-165 | 165 mm |

Mechanical Diaphragm Pump - Head Materials

To ensure compatibility with a wide range of chemicals we offer a number of different head materials which include:-

- 316 Stainless Steel

- PolyPropylene

- PVC

- PVDF

Mechanical Diaphragm Pump - Stroke Length

The PTFE diaphragm is attached to a piston which is in turn driven by the motor and gearbox assembly. Each movement of the PTFE diaphragm is driven by the piston, ensuring the amount of fluid displaced is both linear and repeatable, allowing us to accurately dose the required amount of chemical into an application.

As the length of stroke increases, the amount of fluid transferred during the positive cavity displacement increases. The TAM2, TAM4, and TAM6 have a 2mm, 4mm and 6mm stroke length respectively.

Each the motor driven diaphragm pumps has a micrometer stroke adjustment dial which means that the strong-stroke length can be adjusted across a range of 0 - 100%. By reducing the stroke length, the amount of chemical delivered by the mechanical diaphragm pump can also be reduced. The relationship between the stroke length and volume delivered is linear, allowing us to continue to dose in an accurate and repeatable manner.

To ensure the chemical dosing is accurate and repeatable, we recommend that the stroke length isn't adjusted below 20% of the rated stroke length.

Mechanical Diaphragm Pump - Gear Box

The mechanical diaphragm dosing pumps use a fixed ratio mechanical gearbox which translates the rotation of the motor to the reciprocating action of the piston. By changing the ratio we can increase or decrease the number of strokes per minute that the piston dosing pump makes.

These give us the following output speeds:-

- 58 stokes / minute

- 78 stokes / minute

- 116 strokes / minute

With a known volumetric displacement taking place we can accurately calculate the amount of chemical delivered per stroke. By increasing the number of strokes per minute we can increase the amount of chemical delivered by the pump to achieve the desired flow rate.

In some applications where viscous solutions are dosed or where chemicals have a low vapour pressure, using a lower or higher number of strokes per minute respectively, can offer significant advantages. If you're unsure as to the right gearbox ratio to use for your application, please don't hesitate to contact us.

TAM Mechanical Dosing Pump Range

ATM Mechanical Dosing Pump Range

ATM Diaphragm Microprocessor Dosing Pump

The ATM Series of microprocessor controlled mechanical diaphragm dosing pumps have man

Piston pumps are suited for a wide range of dosing applications.

This includes higher viscosity liquid along with higher flow rates of up to 1000 litres per hour. The range of control functions available make these pumps ideal for numerous applications including the proportional dosing of polyelectrolytes when selected with stainless steel wetted parts and a flooded suction installation.